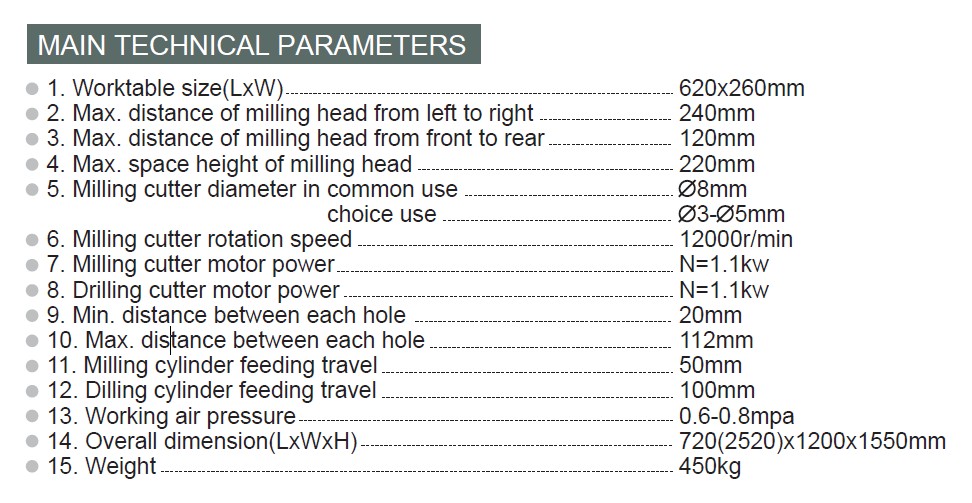

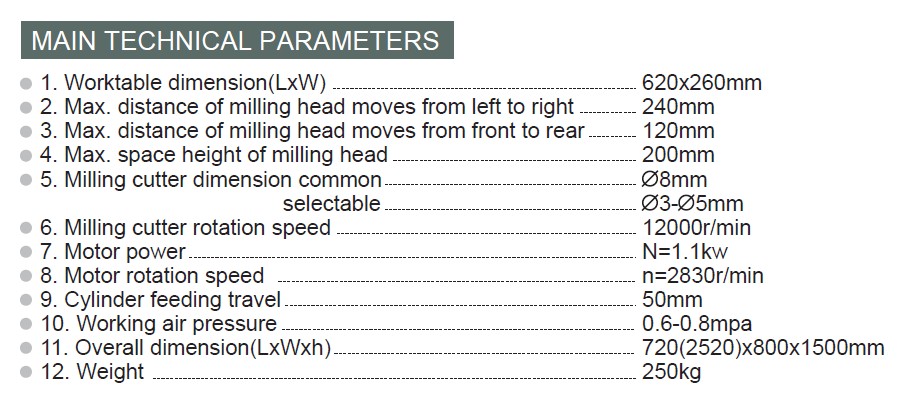

This machine is a semi-automatic drilling andcopy router specialy suitable for big size process.In order to help in the drilling phase, the machinehas been equipted with three adjustable boresthat can effectively lock the profile in placewhile the mill work on it to reproduce the mainform. It can also accuratly replicate the holespresent on any master plate.The adjustable speed rate fuction allows theuser a better control of the work.This machine uses 1:1 ratio for better controlduring milling process.Milling speed rate can be fully adjusted allowingthe worker to have an excellent control over thework.

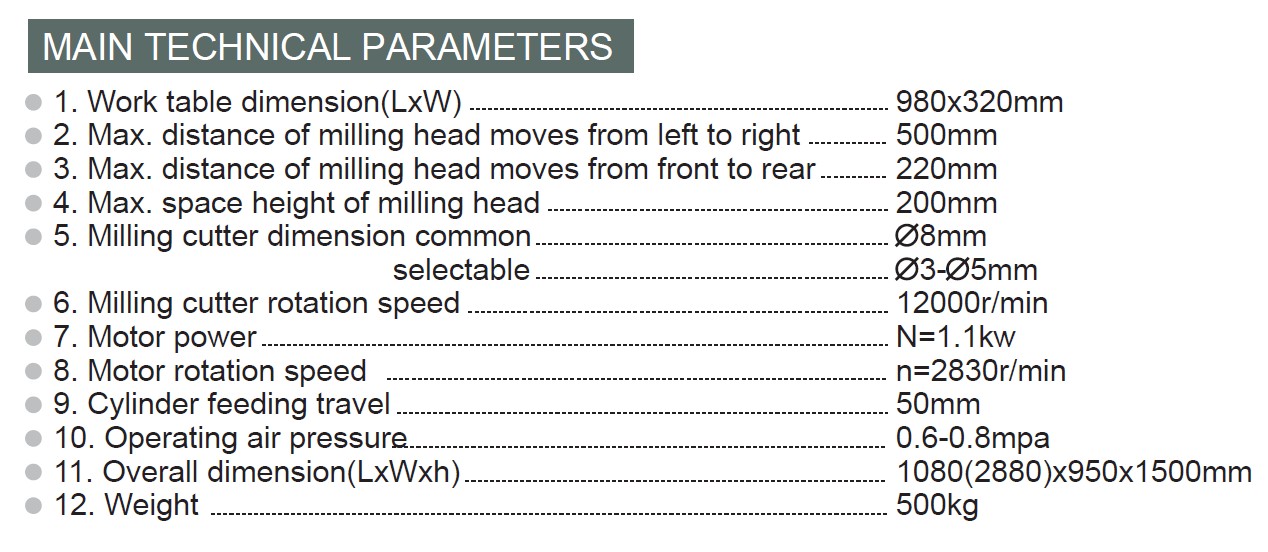

This machine uses a semiautomaticcopy function suitablefor big size process. The accuracyof this machine is high, speciallywhen used to reproduce boreprocess of every kind of shape onaluminum alloy curtain wall, windowprofiles.All shapes will be accuratlyreplicated using the 1:1 ratio.

This machine uses a semi-automatic copy control function, whichprocess profile quickly and accurately. This machine is speciallyfits for processing various kinds of holes of curtain wall and windowprofiles. Bases on the 1:1 ratio, it is capable to perfectly replicateany kind of holes present on the main profile into the target one.

This machine is capable of replicating complicated holes from to master sample. By adjusting the stopperat the left of the end milling head and the positioning bar on the profile bracket, you can mill rectangularshaped holes.All movements take place on the linear axis, while forming pin can rotate freely, allowingeasy and flexible operation. Startup switch is located at the control lever. The lever is equipted with jointbearing for easy operation. Pneumatic clamping operation, highly automatic. Rotating positioning blockallows three different kinds of milling depth. All linear movement bearings and milling cutters aremanufactered in Germary because there are more durable and smoother.

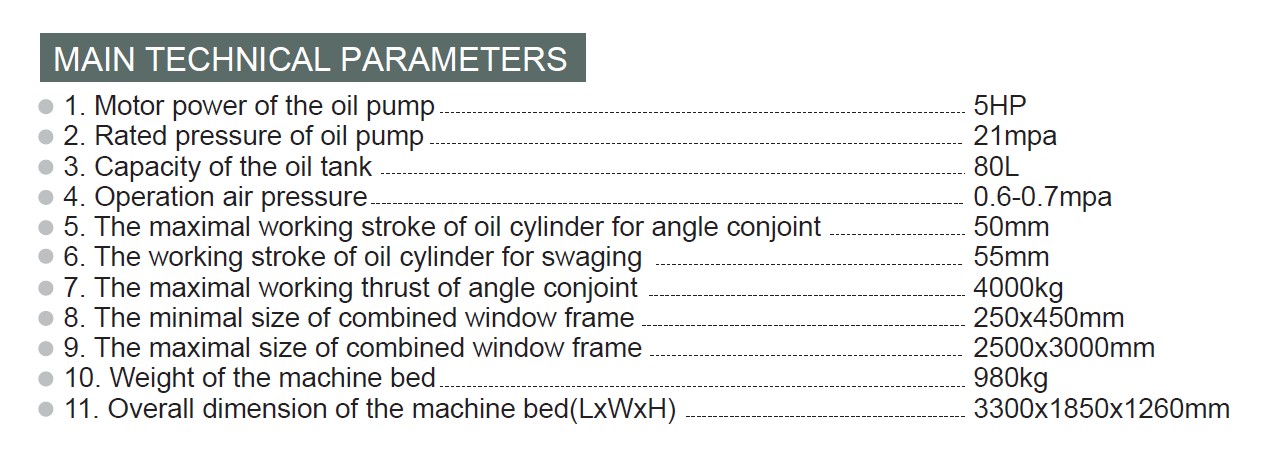

KT338B is a hydraulic double-angle mitre-joint tapping machine, which is a new generation of equipmentproducing high-grade aluminum doors and windows. It has large carrying capacity and tremendous power.Panasonic PLC+ touch screen is used for its control system. The angle joiningt process can be performedmanually or automaticaly . Advanced multi-pressure control valve is used to the form the 90 degree angle,which makes it more convenient to perform adjustment on the machine for large-scale production. The linearbearing + linear guide rail are both imported from South Korea which guarantee that the level of precisionavailable on this machine will undoubtly help you improve from you current production standard. The machineis also easy to operate and convenient to adjust. It is the first choice of high-grade aluminum doors and windowsmanufactuers who are looking to improve both their quality and overall productivity.

Put the corner key into the 45 aluninum alloy window profile, move the bump folks, squeeze the two windowprofile tightly and make a 90 angle firmly. You can adjust the machine to 1-side-four-point crimpingaccording to the characteristic of the gusset. Because of enlarging the size and the crimping force, it is anideal choice for the corner crimping of thermal-break door, window profiles and extremely thick curtain wallmaterials.

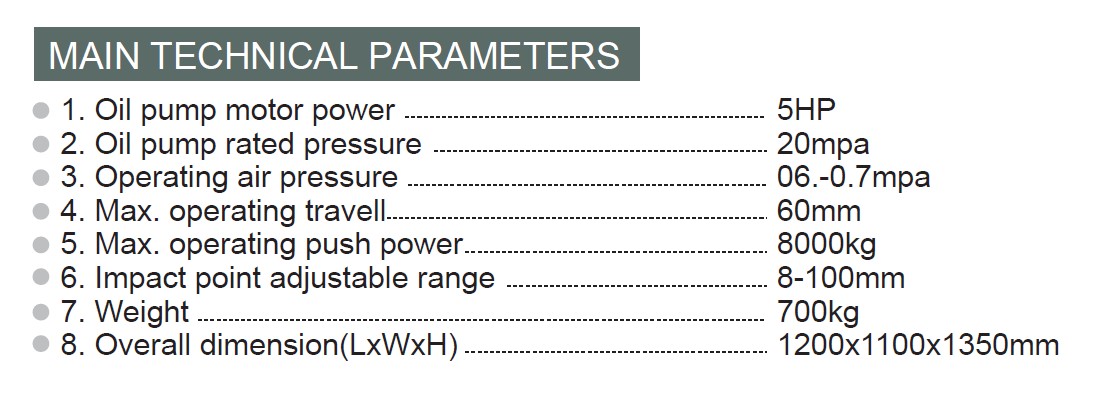

This corner crimping machine can hold two 45 degree pre-cut aluminums alloy window profile, and joint them together to create a robust 90 degree corner by pressing the bumps fork and squeezing them tighly.Due to its ability to perform four points bumps according to angel code characteristics, it is well suited forangel forming for heat insulation frame profile both for windows and doors.

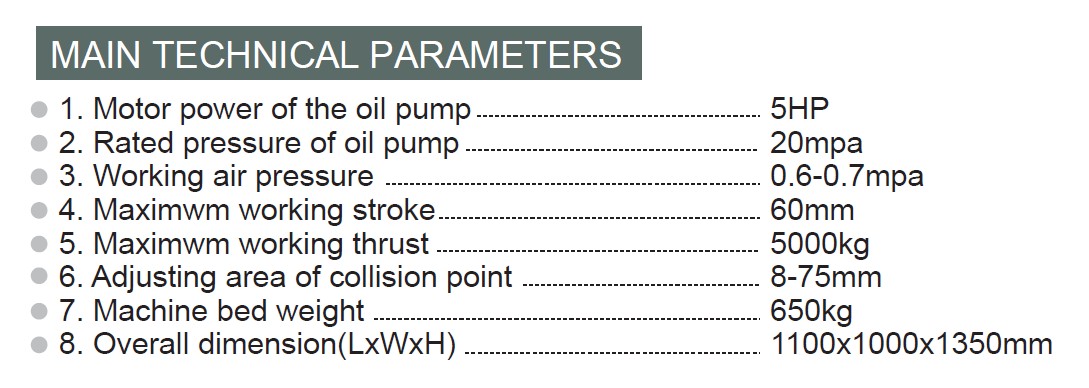

This corner crimping machine can hold two 45 degree pre-cut aluminums alloy window profile, and joint themtogether to create a robust 90 degree corner by pressing the bumps fork and squeezing them tighly.Due to its ability to perform four points bumps according to angel code characteristics, it is well suited for angelforming for heat insulation frame profile both for windows and doors.

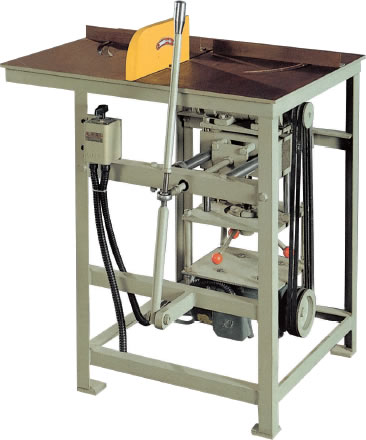

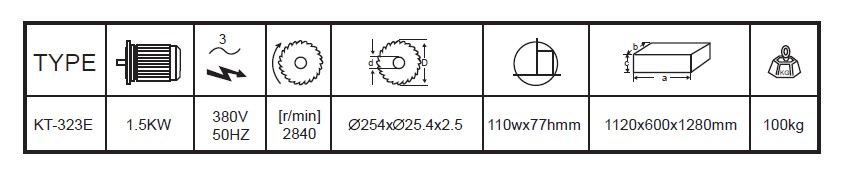

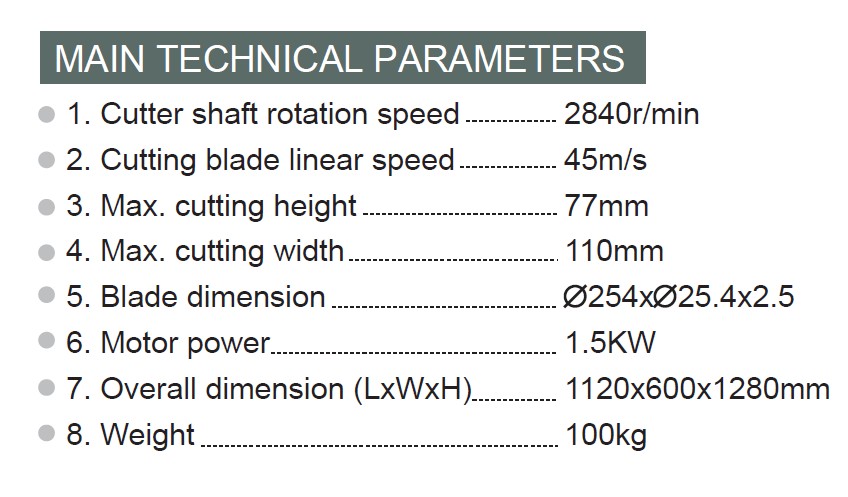

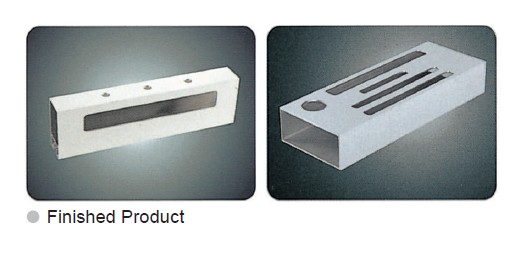

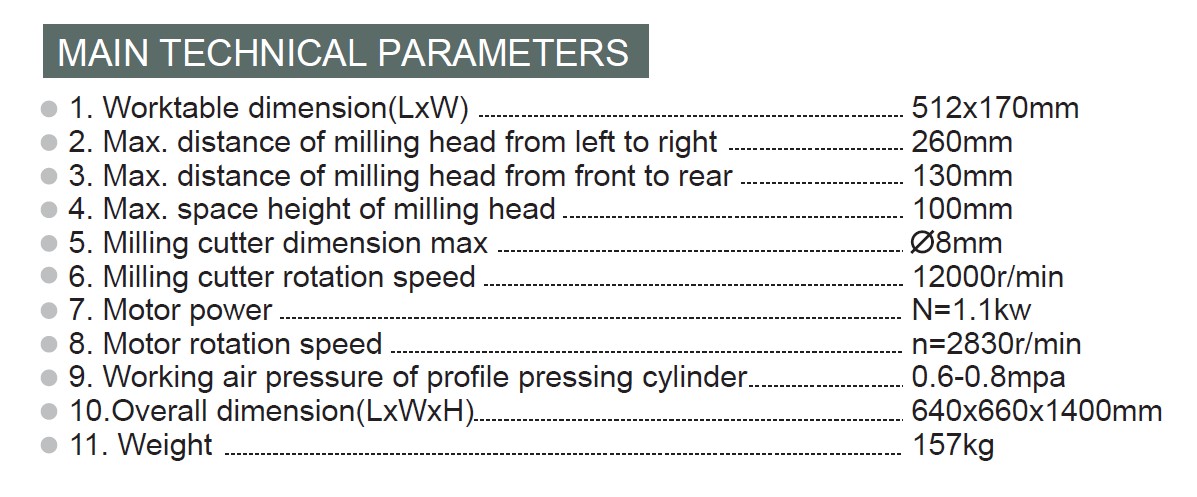

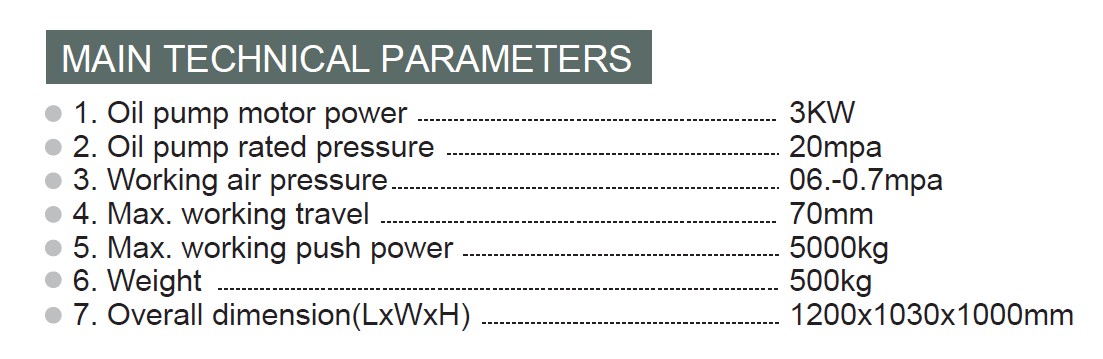

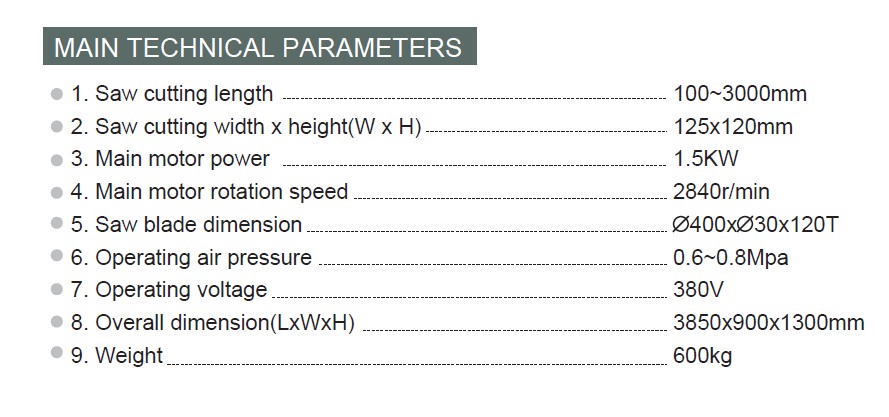

Mainly use in Aluminum alloy curtain wallmateriais, cutting blanking of window sectionsand plastic materials. With the hard alloy sawblades, the outside diameter can reach 16",and also can achieve high linear velocity andhigh precision. This machine is equipted witha dimension location housing. However, adigital display can be added drasticallyincreasing it's accuracy.The workbench can be rotated between(-45 ) and (+45 ) degree.Alumrex' s engeeners have specially designedit for cutting aluminum windows & doors profilesand aluminum curtain wall with various angles.

Primarily used for the cutting of all kinds of aluminum metal alloy window profile this saw is manually operatedand offers the posibility to cut in different angles.